Back to Top

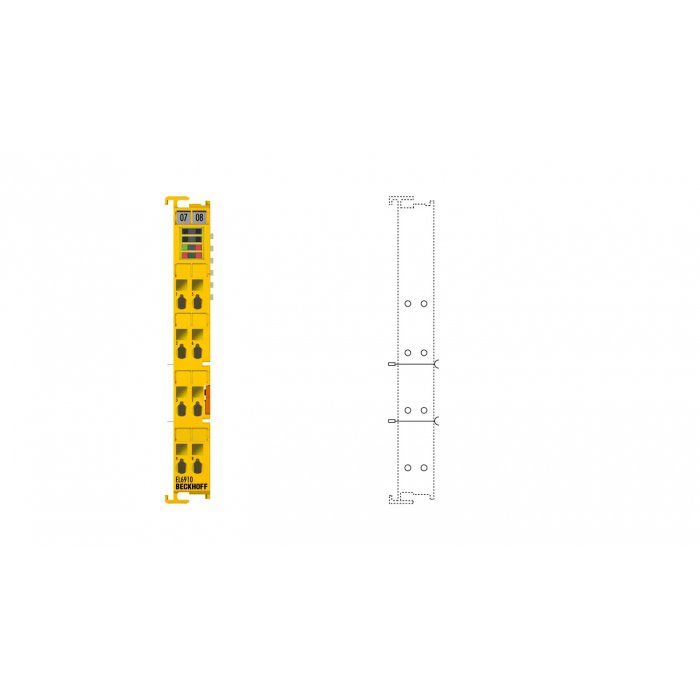

EtherCAT Terminal communication interface EL6910

Specification: link unit between safe input and output signals

Protocol: TwinSAFE/Safety over EtherCAT

Cycle time: approx. 1 ms/according to project size

Fault response time: ≤ watchdog time (parameterizable)

Current consumption power contacts: –

Current consumption E-bus: typ. 160 mA

Installation position: horizontal

Safety standard: EN ISO 13849-1: 2015 (Cat. 4, PL e) and EN 61508: 2010 (SIL 3)

Weight: approx. 50 g

IP protection rating: IP20

Ex marking: IECEx:

Ex ec IIC T4 Gc

Design form: compact terminal housing with signal LEDs

Material: polycarbonate

Dimensions (W x H x D): 12 mm x 100 mm x 68 mm

Installation: on 35 mm DIN rail, conforming to EN 60715 with lock

Side by side mounting by means of: double slot and key connection

Marking: labeling of the BZxxx series

Wiring: solid conductor (e), flexible conductor (f) and ferrule (a): spring actuation by screwdriver

Connection cross-section: s*: 0.08…2.5 mm²,

st*: 0.08…2.5 mm²,

f*: 0.14…1.5 mm²

Connection cross-section AWG: s*: AWG 28…14,

st*: AWG 28…14,

f*: AWG 26…16

Stripping length: 8…9 mm

Current load power contacts: Imax: 10 A

The EL6910 represents the new generation of dedicated safety controllers. While the EL6900 as its predecessor provided only function blocks based on Boolean values, the EL6910 offers a wide variety of certified function blocks that enable the safe processing of analog values and thus the implementation of even more complex safety applications.

In addition to the extension of the processable data types, the so-called customizing function has been established in order to be able to appropriately map current requirements for non-safety-oriented applications with regard to modularization and dynamization in the field of safety technology too. Customizing allows modules of the safety application to be configured so that they are capable of being permanently or temporarily disabled. The disablement or re-enablement can also take place subsequently at runtime.

The EL6910 TwinSAFE Logic can establish 212 connections to other devices. In addition to safe communication connections via FSoE, connections via PROFIsafe are also possible (master and slave). TwinSAFE SC technology is also supported. This technology allows analog signals from the actual standard EtherCAT I/Os (with the identifier -009x) to be safely transmitted to a TwinSAFE Logic-capable component and used there to check the plausibility of this analog signal and to use it in terms of safety using another diversified analog signal (usually up to PL d).

Another highlight of the introduction of the new controller generation is the incremental download. In contrast to its predecessor, the safety project now consists of four components (logic, parameters, mapping, info data), each of which has its own checksum. Thus, in the event of a change to the safety project, an effect analysis can be performed on the basis of these sub-checksums. This simplifies the validation and verification of the safety project. This division is also reflected in the extended user management, so that rights can now be granted on the basis of different components (e.g., a user who can only change the information data of a safety project).

Finally, the new generation of safety controllers now has a diagnostic history directly on the component. All errors that have occurred can be read directly from the component and evaluated.

The EL6910 is programmed using the TwinCAT 3 Safety Editor.

Special features:

analog value processing

incremental download

diagnostic history directly on the component

up to 212 safe connections

up to 128 TwinSAFE groups

up to 512 function blocks

up to 40 users

PROFIsafe master and slave support

TwinSAFE SC support

Write Your Own Review

Write your content here...